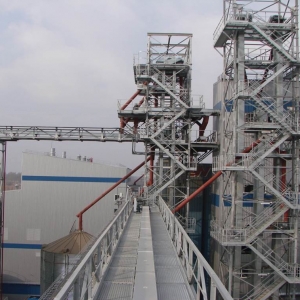

Construction of soybean processing oil extracting plant, after-effect class СС3

Client: ASTARTA-KYIV

Construction site address: Karla Marksa street, 203, Hlobyne, Poltava region

Scope of works fulfilled by ETUAL:

- General project designer

- General Contractor (incl. construction)

- Production and mounting of steel structures

Project description:

Integrated soybean processing plant was put into operation in early 2014. The plant crushes soybeans and processes it into feeding high-protein toasted meal, soybean oil and granulated soy shell. The plant also includes silo storage and storage capacities for finished goods, as well as the necessary engineering, road and rail communications.

Plant is successfully integrated into the production cycle of ASTARTA Holding and has high level of self-sufficiency in raw materials. The complex is equipped by leading manufacturers and all equipment is certified in accordance with international standards. High production water and air treatment systems are installed at the plant.

Production of high quality goods is one of ASTARTA’s top priorities. Soybean processing plant has high quality control system to monitor all stages of production process - from acceptance of soybean through production of finished products, as well as adherence to high environmental standards and requirements.

Plant finished goods - soybean meal, soybean hydrated oil and granulated soybean shell – have already gained high ranks among domestic and international producers of poultry, livestock and aquaculture products.

Production capacities:

- soybean crushing capacity – 700 tons/day or 220 000 tons/year

- high-protein toasted meal - 160 000 tons/year

- soybean oil - 40 000 tons/year

- granulated soybean shell - 10 000 tons/year

- silo storage capacity – 42 000 tons

- area under construction – 7 000 sq.m.

Client web-site: startaholding.com

About the plant at the Client's site: plant

Information on Internet: